Ultrasonic level meter

Ultrasonic level measuring instrument, taking the advantages of various many level measuring instruments, is a universal one characterized by total digitalized and humanized design. It has perfect level monitoring, data transmission and man-machine communication.

-

Tel:

+86 13353783678 -

E-mail:

info@hbmeter.cc

Product description

It is featured by strong anti-interference performance; free setting of upper and lower limits and online output regulation, on-site indication, optional analog, switching value, and RS485 output and easy connection with main unit. The cover, made of waterproof engineering plastics, is small and firm with ABS probe. Therefore, it is applicable for various fields concerning level measuring and monitoring. According to the practical situation, it also can add other modules, such as RS 485, current output; it can be match with PLC better.

Characteristics

- 01DC12-24V wide work voltage

- 02Backup and recovery parameter set

- 03Free adjustment of the range of analog output

- 04Set a filter value to remove

- 05Custom serial port data format

- 06Optional increment/difference distance measurement to measure air space or liquid level

- 071-15 transmitted pulse intensity depending on working conditions

More choices depend on your requirement, as bellowing

- 013 NPN output

- 012 relay output

- 01Voltage output

- 01RS485output connect with PC

- 01Explosion-proof

technical parameter

| Range | 5、8、10、12、15m |

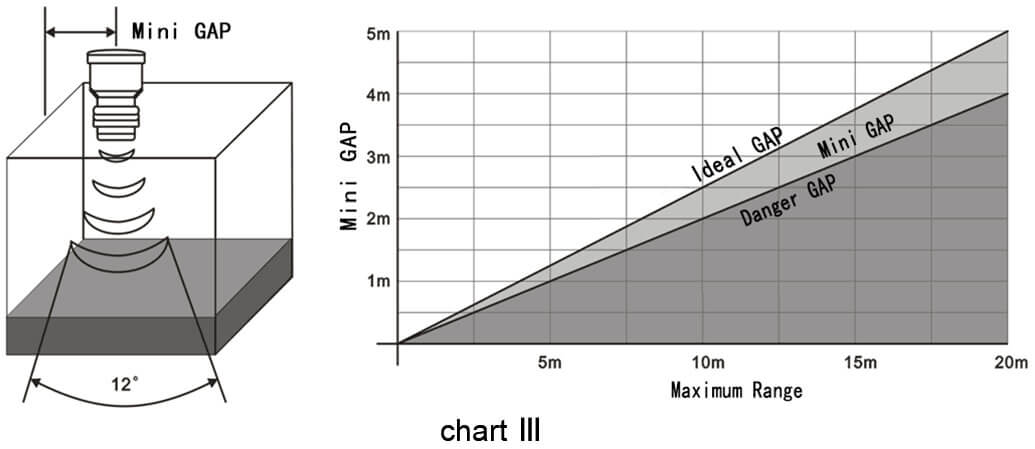

| Blind zone | <0.4-0.5m(different for range) |

| Measure error | 0.3%F.S |

| Display | OLED |

| Display resolution | 1mm |

| Frequency | 20~350KHz |

| Power | 12-24VDC |

| Power consumption | <1.5W |

| Output (optional) | 4~20mA RL>600Ω(standard) 1~5V\1~10V RS485 2 NPN 2 relays (AC 5A 250V DC 10A 24V) |

| Material | ABS |

| Dimension | Φ92mm×198mm×M60 |

| Electrical interface | M20X1.5 |

| Installation | M60X2 or ¢61MM |

| Operating surroundings | normal temperature, normal pressure |

| Protection degree | IP65(others optional) |

Sensor installation

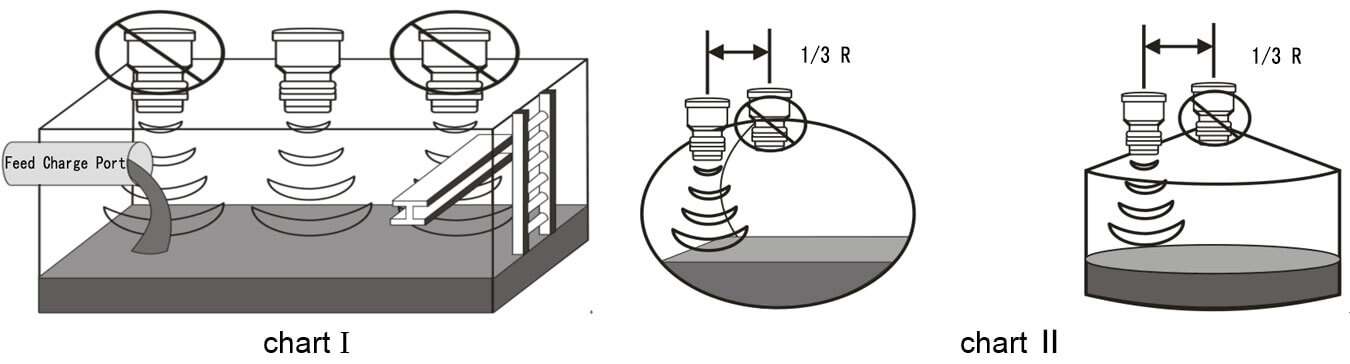

5.1.1 Sensor should be placed where there is no obstacle between emission surfaces and measured liquid, it also should be far way from feeding throats, chartⅠ.

5.1.2 Tank shape should be considered. Some type of container will bring second echo, especially conical and spherical tank. A good installation place will solve the problem, chart Ⅱ.

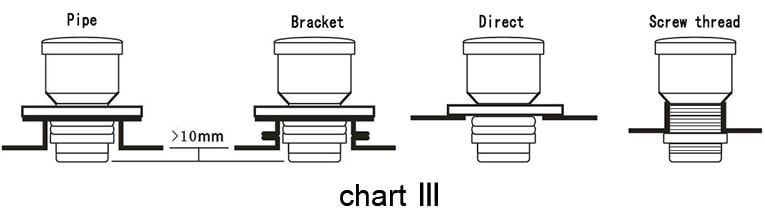

5.1.3 Lever meter can be installed by flange or ¢61 hole, whatever installation way, make sure the sensor bottom through the installation hole or flange, chart Ⅲ.

5.1.4 If the liquid to be measured has sewage, afloat impurities or fluctuation, use a waveguide and the diameter of the waveguide should over 120mm, chartⅣ

5.2 Work mode

5.2.1 Measure liquid level

B(Installation Height)is the distance from bottom of container to sensor surface,A is the distance between sensor surface and liquid surface,D is the height of liquid,D= B(Installation Height)-A,display value is bottom of container to liquid surface(D).

5.2.2 Measure air distance

Set BD =0,display value is distance from sensor surface to liquid surface(A).

5.3 Environment and Filtering This instrument default dynamic filtering, to avoid the filter interference of mixing, tank walls, and other fixed bars. But for totally enclosed small space or other easily formed secondary echo environment, it’s not reliable. When the display value is about twice the actual value regularly, change “Environment”to“Closed”。

5.4 DC12V power is better. When it’s from switch power, the DC negative must contact ground. Refer to the tags attached on the instrument for wiring. In order to keep it working reliable and display precise , please electrify >15 minutes before work. When operated outdoors, it should be placed under a sun screen to avoid direct under sunshine and rain. Lightning proof measures should also be taken out door.