Split Electromagnetic Flowmeter

HBLD intelligent electromagnetic flow meter is a high-performance, high-reliability flow meter. Used to measure the volume flow of conductive liquid and slurry in closed pipes. Widely used in steel, electricity, petroleum, chemical industry, coal, metallurgy, papermaking, water supply and drainage, food, pharmaceutical industry, etc.

-

Tel:

+86 13353783678 -

E-mail:

info@hbmeter.cc

Working principle

The measuring principle of electromagnetic flow meter is based on Faraday's law of electromagnetic induction. The sensor is mainly composed of a measuring tube with an insulating lining, a pair of electrodes installed by inserting the measuring tube wall, a pair of coils and an iron core to generate a working magnetic field. When a conductive fluid flows through the measuring tube of the sensor, a voltage signal proportional to the average flow rate of the fluid will be induced on the electrode. The signal is operationally amplified and processed to achieve various display functions.

Features

-

- 01Measurements are not affected by fluid density, viscosity, temperature,pressure and conductivity.

- 02No obstacles in the measuring tube, no pressure loss, low requirements for straight pipe section.

- 03The LCD backlight type converter can be easily displayed and read in the sun or in a dark room.

- 04In harsh environments, parameters can be set via infrared touch buttons without opening the cover of the converter (need to be customized).

- 05Flow meter with bidirectional measurement system, built-in three totalizers: positive total, reverse total and total difference.

- 06It has various forms of output: current 4-20mA, pulse, frequency, rs-485, HART.

- 07The converter has self-diagnosis alarm output, no-load detection alarm output, flow upper and lower limit alarm, batch control (need to be customized) and other alarm output functions.

- 08Not only for general processes, but also for the measurement of ore pulp, mud, coal slurry, paper pulp and paste liquid.

- 09High-pressure electromagnetic flow sensor with PFA lining technology, resistant to high pressure and negative pressure, especially suitable for petroleum, chemical and other industries.

- 10Explosion-proof instruments can be used in corresponding explosion-proof places.

Product Exhibition

| ————————Technical parameter——————— | ||

|

|

Applicable medium | Various conductive liquids; |

| Caliber range | DN3-DN3000 (DN3\DN4 is flange clamping type) | |

| Lining type | Polychloroprene rubber, PTFE, F46, PFA, silicon fluoride, polyurethane rubber; | |

| Electrode type | 316L, Ha B, Ha C, titanium, tantalum, platinum-iridium alloy, stainless steel tungsten carbide | |

| Pressure range | 0.6~42Mpa; (high pressure needs to be customized) | |

| Temperature resistance | -25~80℃; | |

| Accuracy | ±0.5%, can be customized ±0.3%, ±0.2%; | |

| Protection level | Sensor IP65\IP67\IP68 (optional), converter IP65 | |

| Integrated electromagnetic Flow meter | Output type | Frequency, pulse, 4-20mA, RS485, Modbus protocol; Hart protocol (optional), Profibus DP (optional): |

| Power supply | 85~250V, 45~63Hz, 20VDC --- 36VDC | |

| ————————Technical parameter——————— | ||

|

Applicable medium | Various conductive liquids; |

| Caliber range | DN3-DN3000 | |

| Lining type | Polychloroprene rubber, PTFE, F46, PFA, silicon fluoride, polyurethane rubber; | |

| Electrode type | 316L, Ha B, Ha C, titanium, tantalum, platinum-iridium alloy, stainless steel tungsten carbide | |

| Pressure range | 0.6~42Mpa; (high pressure needs to be customized) | |

| Temperature resistance | -25~80℃; | |

| Accuracy | ±0.5%, can be customized ±0.3%, ±0.2%; | |

| Protection level | Sensor IP65\IP67\IP68 (optional), converter IP65 | |

| Split electromagnetic Flow meter | Output type | frequency, pulse, 4-20mA, RS485, Modbus protocol; Hart protocol (optional), Profibus DP (optional) |

| Power supply | 85~250V, 45~63Hz, 20VDC --- 36VDC | |

| Flow rate table | |||||||

| mm,m3/h,m/s | 0.5 | 1 | 2 | 3 | 4 | 5 | 15(maximum) |

| 10 | 0.14 | 0.28 | 0.27 | 0.85 | 1.13 | 1.41 | 4.24 |

| 15 | 0.32 | 0.64 | 1.27 | 1.91 | 2.54 | 3.18 | 9.54 |

| 20 | 0.57 | 1.13 | 2.26 | 3.39 | 4.52 | 5.65 | 16.96 |

| 25 | 0.88 | 1.77 | 3.53 | 5.30 | 7.07 | 8.84 | 26.51 |

| 32 | 1.45 | 2.90 | 5.79 | 8.69 | 11.58 | 14.48 | 43.43 |

| 40 | 2.26 | 4.52 | 9.05 | 13.57 | 18.10 | 22.62 | 67.86 |

| 50 | 3.53 | 7.07 | 14.14 | 21.21 | 28.27 | 35.34 | 106.03 |

| 65 | 5.97 | 11.95 | 23.89 | 35.84 | 47.78 | 59.73 | 179.19 |

| 80 | 9.05 | 18.10 | 36.19 | 54.29 | 72.38 | 90.48 | 271.43 |

| 100 | 14.14 | 28.27 | 56.55 | 84.82 | 113.10 | 141.37 | 424.12 |

| 125 | 22.09 | 44.18 | 88.36 | 132.54 | 176.71 | 220.89 | 662.68 |

| 150 | 31.09 | 63.62 | 127.23 | 190.85 | 254.47 | 318.09 | 954.26 |

| 200 | 56.55 | 113.10 | 226.19 | 339.29 | 452.39 | 565.49 | 1696.46 |

| 250 | 88.36 | 176.71 | 363.43 | 530.14 | 706.86 | 883.57 | 2650.72 |

| 300 | 127.23 | 254.47 | 508.94 | 763.41 | 1017.88 | 1272.35 | 3817.04 |

| 350 | 173.18 | 346.36 | 692.72 | 1039.08 | 1385.44 | 1731.80 | 5195.41 |

| 400 | 226.19 | 452.39 | 904.78 | 1357.17 | 1809.56 | 2261.96 | 6785.84 |

| 450 | 286.28 | 572.56 | 1145.11 | 1717.67 | 2290.22 | 2862.78 | 8588.33 |

| 500 | 353.43 | 706.86 | 1413.72 | 2120.58 | 2827.43 | 3534.29 | 10602.88 |

| 600 | 508.94 | 1017.88 | 2035.75 | 3053.63 | 4071.50 | 5089.38 | 15268.14 |

| 700 | 692.72 | 1385.44 | 2770.88 | 4156.33 | 5541.77 | 6927.21 | 20781.64 |

| 800 | 904.78 | 1809.56 | 3619.11 | 5428.67 | 7238.23 | 9047.79 | 27143.36 |

| 900 | 1145.11 | 2290.22 | 4580.44 | 6870.66 | 9160.88 | 11451.11 | 34353.32 |

| 1000 | 1413.72 | 2827.43 | 5654.87 | 8482.30 | 11309.73 | 14137.13 | 42411.50 |

| 1200 | 2035.75 | 4071.50 | 8143.01 | 12214.51 | 16286.02 | 20357.52 | 61072.56 |

| 1400 | 2770.88 | 5541.77 | 11083.54 | 16625.31 | 22167.08 | 27708.85 | 83126.54 |

| 1600 | 3617.11 | 7238.23 | 14476.46 | 21714.69 | 28952.92 | 36191.15 | 108573.44 |

| 1800 | 4580.44 | 9160.88 | 18321.77 | 27482.65 | 36643.54 | 45804.42 | 137413.26 |

| 2000 | 5654.87 | 11309.73 | 22619.47 | 33929.20 | 45238.93 | 56548.67 | 169646.00 |

| 2200 | 6842.39 | 13684.78 | 27369.56 | 41054.33 | 54739.11 | 68423.89 | 205217.66 |

| 2400 | 8143.01 | 16286.02 | 32572.03 | 48858.05 | 65144.07 | 81430.08 | 244290.24 |

| 2600 | 9556.72 | 19113.43 | 38226.85 | 57340.71 | 76453.71 | 95567.13 | 206701.40 |

| 2800 | 11083.54 | 22167.90 | 44334.15 | 66501.23 | 88668.31 | 110835.39 | 332506.16 |

| 3000 | 12723.45 | 25446.90 | 50893.80 | 76340.70 | 101787.60 | 127234.50 | 381703.50 |

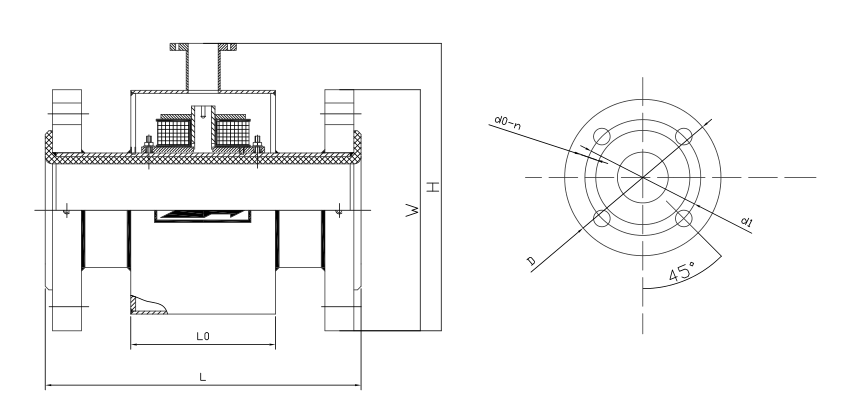

Electromagnetic flow meter sensor dimension drawing

Flange standard: JB/T 81-94(The company's standard product flange standard)

Unit: mm

| Nominal diameter | preset pressure | L | W | H | d1 | d0-n | Nominal diameter | preset pressure | L | W | H | d1 | d0-n |

| DN3 | 4.0 | 192 | 90 | 140 | 60 | ⌀14*4 | DN250 | 1.6 | 450 | 405 | 455 | 355 | ⌀26*12 |

| DN6 | 4.0 | 192 | 95 | 145 | 65 | ⌀14*4 | DN300 | 1.6 | 500 | 460 | 510 | 410 | ⌀26*12 |

| DN10 | 4.0 | 192 | 90 | 140 | 60 | ⌀14*4 | DN350 | 1.0 | 500 | 500 | 550 | 460 | ⌀23*16 |

| DN15 | 4.0 | 192 | 95 | 145 | 65 | ⌀14*4 | DN400 | 1.0 | 500 | 565 | 615 | 515 | ⌀36*16 |

| DN20 | 4.0 | 192 | 105 | 155 | 75 | ⌀14*4 | DN450 | 1.0 | 550 | 615 | 665 | 565 | ⌀26*20 |

| DN25 | 4.0 | 192 | 115 | 165 | 85 | ⌀14*4 | DN500 | 1.0 | 550 | 670 | 720 | 620 | ⌀26*20 |

| DN32 | 4.0 | 192 | 135 | 185 | 100 | ⌀18*4 | DN600 | 1.0 | 600 | 780 | 830 | 725 | ⌀30*20 |

| DN40 | 4.0 | 192 | 145 | 195 | 110 | ⌀18*4 | DN700 | 0.6 | 700 | 860 | 910 | 810 | ⌀26*24 |

| DN50 | 4.0 | 192 | 160 | 210 | 125 | ⌀18*4 | DN800 | 0.6 | 800 | 975 | 1025 | 920 | ⌀30*24 |

| DN65 | 1.6 | 250 | 180 | 230 | 145 | ⌀18*4 | DN900 | 0.6 | 900 | 1075 | 1125 | 1020 | ⌀30*24 |

| DN80 | 1.6 | 250 | 195 | 245 | 160 | ⌀18*8 | DN1000 | 0.6 | 1000 | 1175 | 1225 | 1120 | ⌀30*28 |

| DN100 | 1.6 | 250 | 215 | 265 | 180 | ⌀18*8 | DN1200 | 0.6 | 1200 | 1400 | 1450 | 1340 | ⌀30*32 |

| DN125 | 1.6 | 250 | 245 | 295 | 210 | DN1400 | 0.6 | 1400 | 1620 | 1670 | 1560 | ⌀30*36 | |

| DN150 | 1.6 | 300 | 280 | 330 | 240 | ||||||||

| DN200 | 1.6 | 350 | 335 | 385 | 295 |

More flange standard size reference table (please specify before ordering)